Laboratories & Facilities at the Ruhr-Universität Bochum

Thin Films

Producing thin films of complex refractory materials such as silicates and oxides was not possible in the past. Advances in the techniques of pulsed Laser ablation using an excimer laser have now made it possible to produce such thin films, which enable a variety of diffusion and other kinetic studies to be carried out. A laboratory for the production of such thin films is in place at the Institute of Geology, Mineralogy and Geophysics of the Ruhr-University at Bochum. It is the only one of its kind in the world that is dedicated to the production of thin films of mineralogical interest.

The equipment, built to suit our special needs, consists of an excimer laser capable of operating at three wavelengths (ArF – 193nm, KrF – 248nm and XeF 351 nm). This laser is powerful enough (pulse energies of 650 to 1200mJ, maxium wattage of upto 50 and a frequency of 50 Hz) to convert refractory minerals (targets) stoichiometrically to a plasma. The plasma then deposits the material on the surface of a second solid object (substrate), which is typically the polished/cleaved surface of a mineral or rock.

The high energy ensures tight bonding between the deposited thin film and the substrate, thereby producing excellent starting materials for diffusion and other kinetic or mechanical testing studies while the substrate is tempered.

Among the many advantages of this method are the speed and versatility with which a wide range of chemistry can be handled. We have so far produced, for example, thin films of olivines, garnets, pyroxenes, feldspars, perovskites and various oxides of complex chemistry, similar to those found in nature. We have also produced films of water bearing materials (e.g. micas, hydrous glasses). The deposited area is usually about 4×4 mm.

High Pressure Laboratories

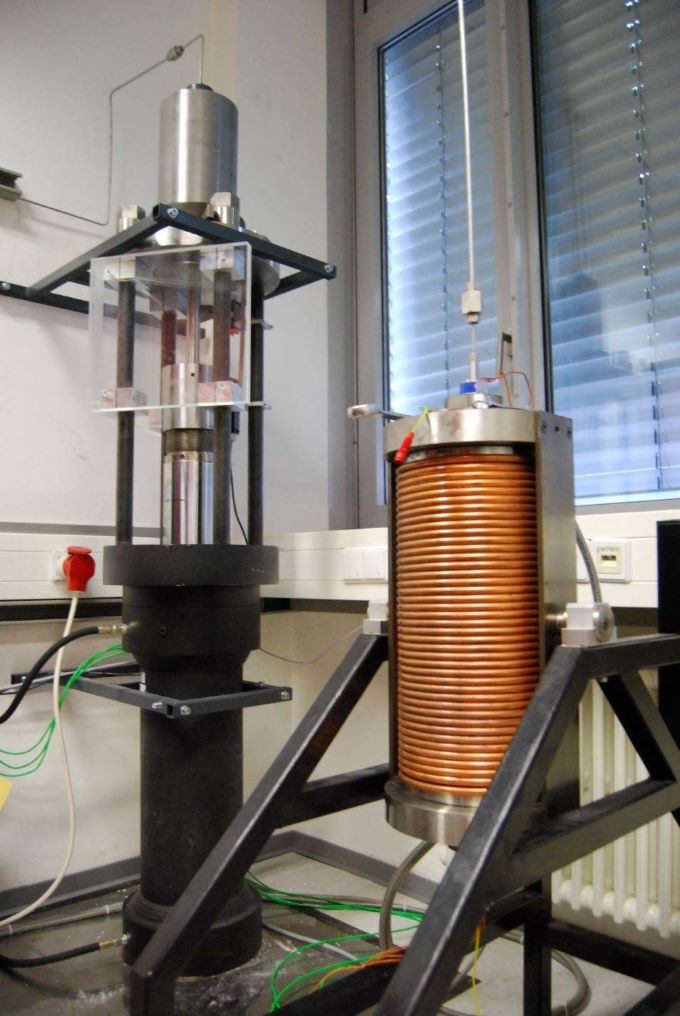

The well equipped High Pressure Laboratories of the Petrology Section of the Institute of Geology, Mineralogy and Geophysics comprise of three units:

Two presses make up the piston-cylinder laboratory. High pressure is obtained in these equipments by compressing specially designed solid-media high pressure cells. Pressures of up to 50 Kbar (~ 5 GPa) and Temperatures of up to 1600°C can be achieved with this kind of equipment.

The presses have computerized pressure and temperature controllers, which can be used to carry out experiments along pre-defined P-T paths. Pressure and Temperature conditions can thus be held at defined conditions for long durations without the need for manual intervention. One of the presses has additional facilities to monitor the piston displacement, which allows compressibility measurements to be carried out at high pressures. Samples of up to 200 mg can be used, at higher pressures only small samples of about 10 mg can be used.

2. Multi-Anvil press

The multianvil press is another kind of solid media high pressure apparatus which allows higher pressures (up to 120 kbar, ~ 12 GPa) and temperatures (up to 1600 °C) to be accessed. The pressurization as well as decompression occurs under computer control in this machine. The sample volumes are even smaller than in the piston cylinder apparatus – it is a general rule of thumb that the higher the pressure, smaller the sample volume.

3. Hydrothermal Autoclave laboratory

About 12 autoclaves, where high pressure is obtained by pumping water into narrow capillaries, make up the hydrothermal laboratory. These are heated externally in a furnace.

Pressures of up to 2 kbar and temperatures of up to 800 °C can be obtained using these equipments.

The main advantage of this kind of equipment lies in the large sample volumes that can be obtained, relatively more hydrostatic pressure (compared to solid-media apparatus)and long run durations of months, during which stable pressure and temperature conditions can be maintained.

High-Temperature Laboratories

The Petrology Section of the Institute of Geology, Mineralogy and Geophysics has a number of high-temperature furnace labs where experiments can be carried out at temperature up to 1800° C. Available facilities include:

Gas-Mixing Furnaces

In these furnaces a mixture of CO2 and CO is used to control the oxidation state of the surrounding atmosphere. This is important for carrying out experiments under reducing conditions such as those found in the interior of the Earth and on other planetary objects (e.g. the Moon, asteroids). Variation of oxidation states can also be used to control the concentration of defects in crystals, which is important for studying and understanding kinetic properties.

VACUUM FURNACE

In this furnace evaporation experiments involving solids and liquids may be carried out at very high temperatures. For example, the vapour phases coexisting with molten magmatic liquids or minerals such as olivines can be studied, along with the isotopic fractionation effects that occur during such evaporation – condensation reactions. It has been shown that such evaporation also affects the nature of surfaces and defects in crystals, and these are aspects that are studied in our research group.

This furnace is located in the buildings of RUBION on the campus of the University.

Optical Laboratory

Optical Properties

The optical properties of solids (minerals, synthetic crystals) are very sensitive physical parameters and can be used to reveal petrological and crystallographic processes as well as technical problems.

Several different kinds of high precision measurements may be carried out in our department:

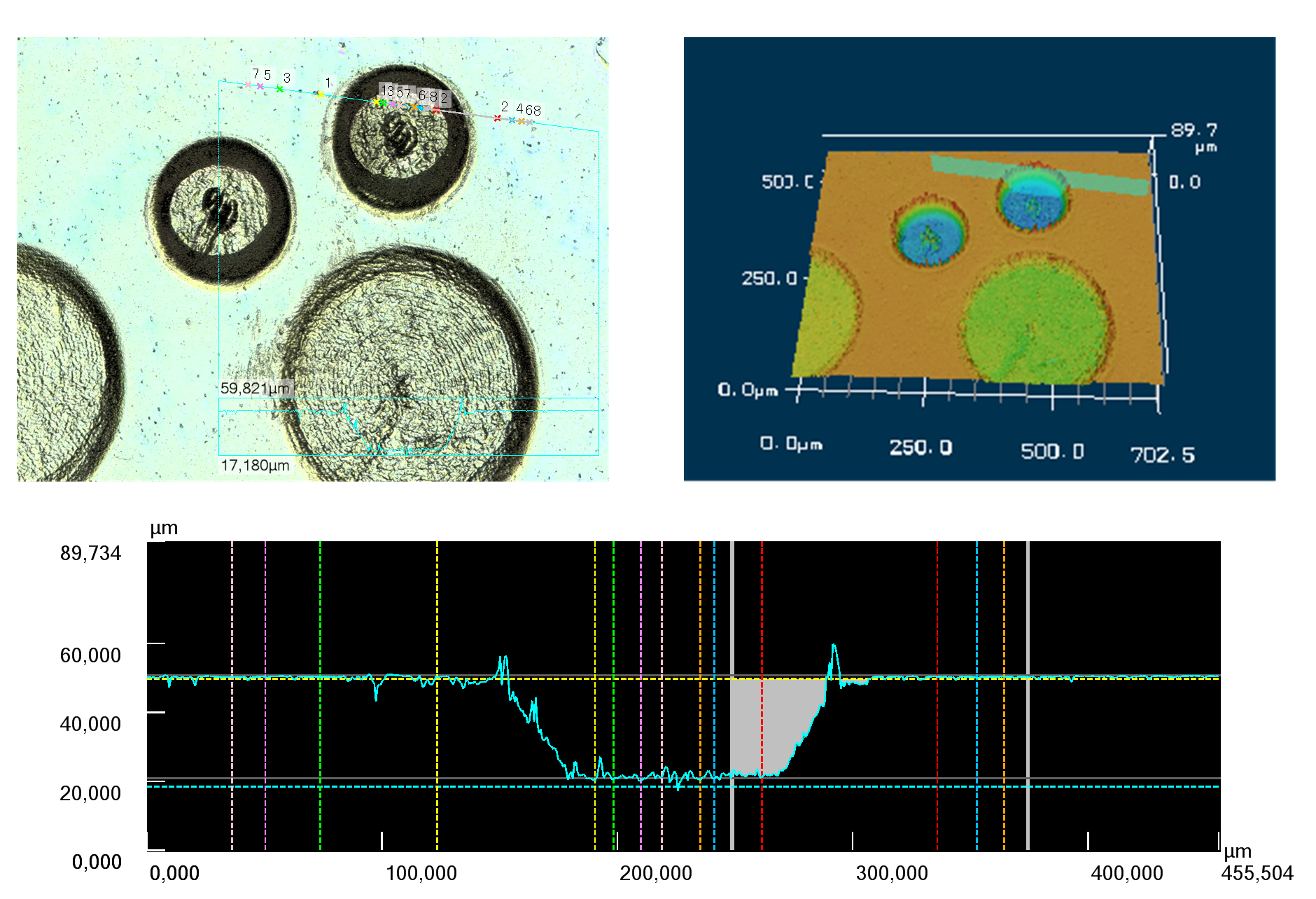

While light interferometer Microscope

We have a white light interferometer microscope which may be used to measure the topography of crystal surfaces with a resolution of nanometers. This is useful for the studies of samples used in diffusion, dissolution, or other kinetic studies. It is also used for the determination of the sizes of depth pits produced during depth profiling in SIMS instruments. This is an essential step for the measurement of concentration profiles using the depth profiling technique in SIMS or LAB ICP MS instruments.

Spindle stage

Spindle stage technique for determination of orientation of crystals, as well as refractive indices:

Currently the equipment is used mostly to orient crystals for use in experimental studies of diffusion and other kinetic properties.

An advanced spindle stage to determine the indices of refraction and the optical angle (2V) has been constructed in our department and is available. For the refractive index measurement, the index of a liquid, whose index matches exactly with that of the unknown crystal, is determined using an internal refractometer. This method thus avoids all external sources of error and the precision of measurements can be increased to ~ 0.0003 for n.

Sample Preparation

Precision Lathe

Diamond wire saw for cutting small samples

Precision Welding machine

Dentist’s tools for machining small parts

Ultrasonic bath and vacuum impregnator

Polishing machine

Chemical Laboratories

The chemistry-lab is able to analyze quantitatively the bulk chemical compositions of any inorganic solid material; e.g. rocks, ores, soils, cements, glasses, metals and alloys, technical products. Special requirements for the samples are given below. Only the inorganic part of fluids can be detected.

Please note: All methods are destructive to the sample!

Atomic absorption spectroscopy (AAS) – VARIAN AA 300

Elements that can be analyzed: all elements with Z > 3 (lithium) requirements: the sample must be soluble in an inorganic solvent, the mass must exceed 1 mg (depends on the number of elements to be analyzed). Coulometric analyses of Carbon, Carbon dioxide, Sulfur, and H2O (in minerals as hydroxyl groups or as H2O, moisture) requirements: mass should exceed 10 mg/analysis (depends on the content).

Potentiometric determination of fluorine and Fe2+: Requirements: mass should exceed 50 mg/analysis (depends on the content) Determination of loss on ignition (l.o.i.).

X-Ray fluorescence spectroscopy (XRF) – PHILIPS PW 2404

Elements that can be detected: all elements with Z > 9 (fluorine) except the nobel gases. Requirements: the mass of the sample should exceed approximately 1 g.

Laboratories & Facilities at the Gottfried Wilhelm Leibniz Universität Hannover

Clean lab with clean-air workstations

We have clean-air workstations that were installed by MK test facilities in 2002 and modernized by Arias GmbH in 2016. Each workplace is equipped with three pipettes (BioHit; 20 -200 µL, 100 – 1000 µL, 500 – 5000 µL). In addition, we offer workstations with two PicoTrace heating plates each for sample digestions. A third workstation is equipped with a PicoTrace heating plate for use with the PicoTrace DAS high-pressure high-temperature digestion system for temperatures up to 230 °C. The system can also be operated with perchloric acid, which is neutralized in an acid neutralization unit. All eight heating plates can be programmed via Arias control modules (including heating and cooling ramps as well as defined operating times).

Further devices:

- separate systems for the production of water with a degree of purity 18.2 MΩ (Millipore Milli-Q Reference or Advantage systems)

- distillations for the production of low blank HNO3 (quartz glass distillate) and HCl (PicoTrace dome distillate)

- microwave digestion system MLS Start + Terminal 640 Programmable for up to 12 samples, vessels made of Teflon® or quartz glass can be used

- an acid neutralization unit can be connected to the microwave if required. programmable centrifuge, max. 5000 rpm / 4472 g (Type 3-15, Sigma Laboratory Centrifuges)

- programmable heatable ultrasonic bath (water temperature adjustable from 20 to 80 °C) (Omnilab)

- Scales: Sartorius CP2201-OCE (max. 2.2 kg), and Sartorius CP225D-OCE (max. 220 g), placed in a separate workstation equipped with three pipettes (BioHit) and an ionizer (Sartorius)

- 4-channel peristaltic pump (Masterflex system, Cole-Parmer Instrument Company)

- programmable overhead shaker, which can hold vessels with volumes of 15 or 50 mL (Intelli-Mixer RM-2-System, laboratory technology)

- vacuum filter system for aqueous samples (Sartorius, System 16510)

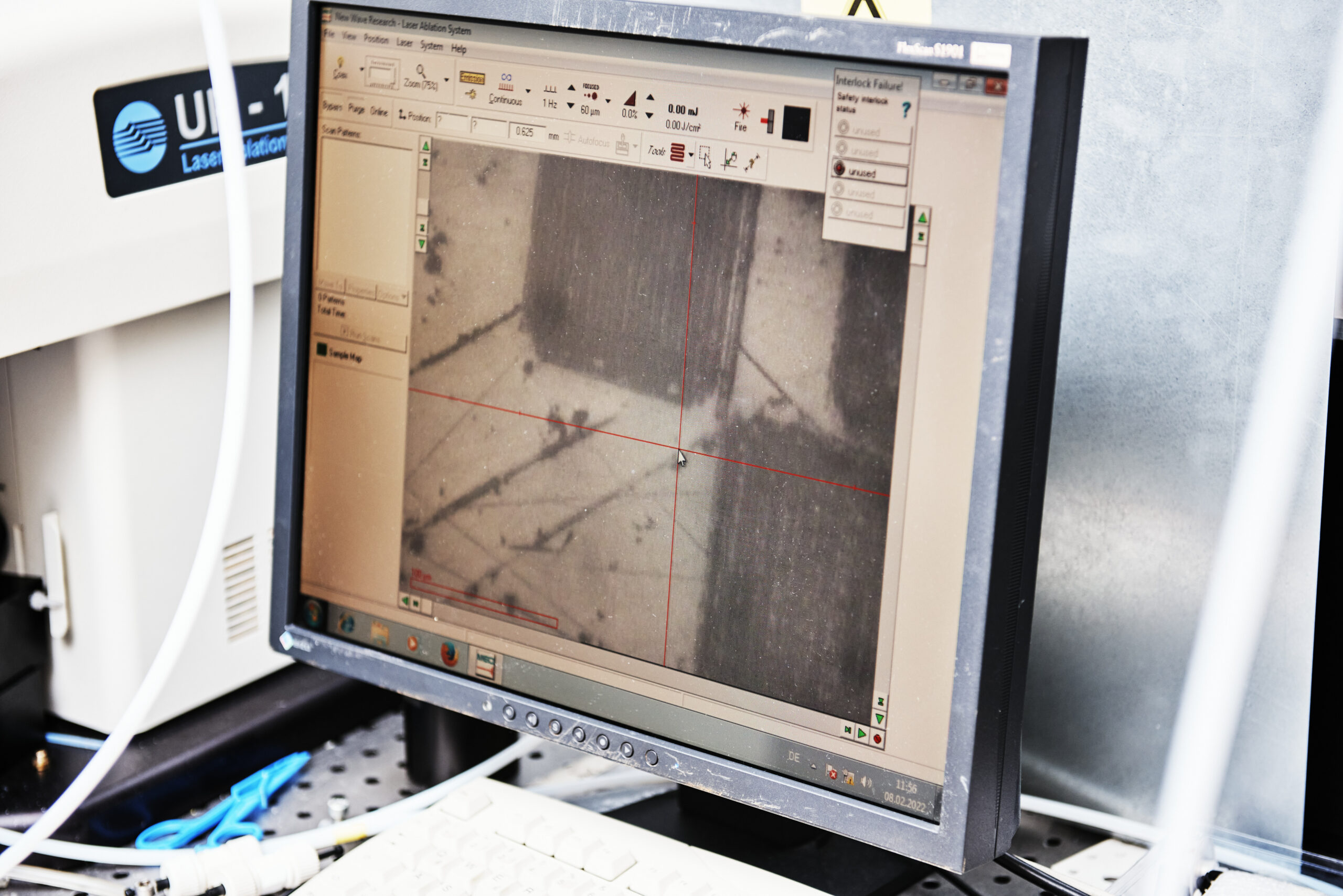

femtosecond laser ablation system

We developed a novel laser ablation system to be used as micro-analytical tool in the elemental and isotope analysis of solid materials. The system is based on a femtosecond all solid-state Ti:sapphire-based Laser operating at a fundamental wavelength tunable between 775-785 nm coupled to a frequency conversion setup to produce deep UV laser radiation at a wavelength of 194 nm. Apart from conventional ablation techniques in spot-, line- or raster mode, we are also able to perform depth profile analyses with a depth resolution of ~1 µm. The system is combined with ICP-based analytical instrumentation (sector field-ICP-MS and MC-ICP-MS). Femtosecond laser ablation is particularly suitable (and used in Hannover) for analyses of the stable isotope composition of metals, e.g. Li, B, Mg, Si, V, Fe, Ni, Cu, Sn and Sb, Because of low thermal interaction between the laser beam and the sample, it can (and is) also used for the analyses of ice.

MC-ICP-MS (ThermoScientific NeptunePlus) for isotope ratio analyses

The study of isotope compositions of different substances is a broad field of scientific research that helps to elucidate processes of e.g. dissolution and precipitation in environmental studies, may provide an age information of rocks and minerals, or the formation of Earth, Moon, and the solar system, just to name a few. For isotope research, multi collector-inductively coupled plasma-mass spectrometry (MC-ICP-MS) represents a versatile and reliable tool for precise analyses of isotope ratios of various elements. The plasma source allows ionization of many elements, either being introduced via an aerosol or a solution.

The The Institute of Mineralogy uses a ThermoScientific NeptunePlus MC-ICP-MS instrument equipped with 9 Faraday detectors, one secondary electron multiplier (SEM, fixed), and two compact discrete dynode (CDD) SEMs for isotopes with very low signal intensities (< 106 cps; attached to the L4 and H4 Faraday detector, respectively). One amplifier with a 1013 Ω feedback resistor can be selected for a low signal intensity (typically < 5×10-13 A ≡ 50 mV), and nine amplifiers with 1011 Ω resistors are installed enabling measurement of signals of up to 5×10-10 A (≡ 50 V).multianvil press is another kind of solid media high pressure apparatus which allows higher pressures (up to 120 kbar, ~ 12 GPa) and temperatures (up to 1600 °C) to be accessed. The pressurization as well as decompression occurs under computer control in this machine. The sample volumes are even smaller than in the piston cylinder apparatus – it is a general rule of thumb that the higher the pressure, smaller the sample volume.

sector field-ICP-MS (ThermoScientific ElementXR) for trace element analyses

Our ThermoScientific ElementXR double-focusing sector field-inductively coupled plasma-mass spectrometer (SF-ICP-MS) is equipped with a Faraday detector and a dynode combined with a secondary electron multiplier (SEM). Hence, it allows detection of a wide range of signal intensities (the dynamic range of counts per second encompasses 1012 cps). This enables the analyses of ultra-trace element levels simultaneously with major elements. Three different modes of mass resolution allow separation of molecular interferences from signal peaks of interest. Except for H, He, C, N, O, and the noble gases, the ElementXR at the Institute of Mineralogy is capable of analyzing every element of the periodic table.

Electron microbeam techniques

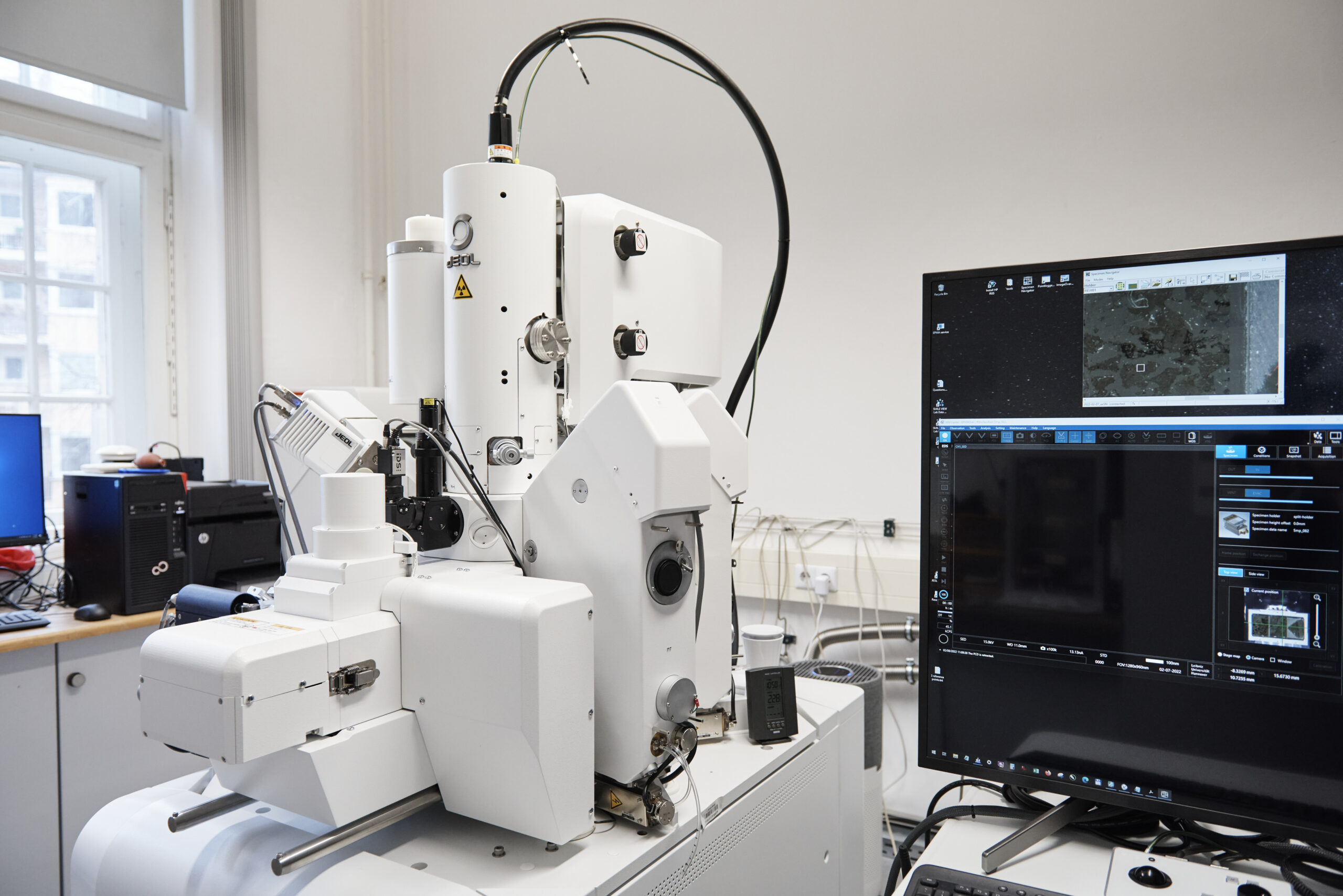

1. electron microprobe (JEOL JXA-iHP200F)

JEOL field emission electron probe micro analyser (EPMA) equipped with 5 WDX spectrometers and an EDX detector allowing the quantitative analysis of elements with atomic numbers higher than 4 (Be).

2. scanning electron microscope (JEOL JSM-7610Plus)

JEOL field emission scanning electron microscope (SEM) equipped with a Bruker EDX system for textural investigation of samples and qualitative chemical analyses.

internally heated gas pressure vessel (IHPV)

Four internally heated pressure vessels (IHPV) are available for experiments at high temperatures (800-1300 °C) and pressures (up to 700 MPa). At H2O-saturated experimental conditions, the intrinsically buffered fO2 corresponds to QFM+3. For two vessels, H2 can be added to the pressurising Ar gas to buffer fO2 at desired levels (ranging from QFM-1 to QFM+3). These vessels are additionally equipped with Shaw-membranes to monitor H2 partial pressures during experiment performance.

Rapid quench externally heated (cold seal) pressure vessels (CSPV)

Two rapid quench externally heated pressure vessels for experiments at conditions up to 850 °C and 400 MPa. Under H2O-saturated experimental conditions, intrinsically buffered fO2 correspond to NNO+2. These vessels are equipped with a magnetic system allowing rapid heating and quenching of samples.

box furnace

Synthesis of starting material glasses at temperatures up to 1600 °C

1-atm gas mixing furnaces

One vertical Gero (Tmax = 1600 °C) and one horizontal Nabertherm (Tmax = 1300 °C) 1-atm gas mixing furnace. Experimental fO2 conditions can be adjusted precisely using either an adjustable mixture of CO2 and H2 gas or Ar-H2 (Varigon H6).